When it comes electronic components, few are quite as important as digital potentiometers. Below, you will find out all the details regarding what they are, how these components work, and why it is usually a good idea to choose these digital variants over the many mechanical alternatives available on the market.

What are digital potentiometers?

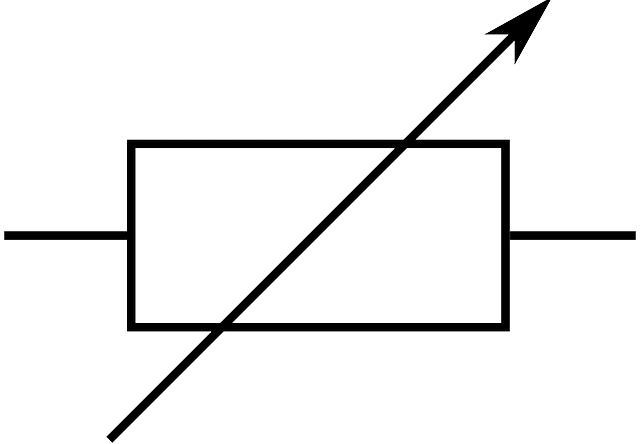

Digital potentiometers are important components used in the design of electronic applications and appliances. They are created to adjust resistance based on an array of signals and offer several advantages compared to mechanical potentiometers.

How they work

In order to comprehend the workings of digital potentiometers, it is important to understand their various components, namely the memory unit, control unit, and a series of resistors. Digital potentiometers are created by joining a series of resistors together in a formation similar to that of a ladder. Each rung on the ladder-like structure is made up of a switch that connects to the potentiometer’s output. The more ‘ladder rungs’ included in the device, the more powerful its resistance.

Most digital potentiometers will come equipped with a volatile memory unit which only operates when the electronic application is on and working. These memory units are usually not capable of storing information following shut down. That is, unless they feature an FPGA to store the last position.

The control unit, also known as the interface unit, is the true core of a digipot. This component is the main differentiator between regular potentiometers and digital potentiometers. It is responsible for adjusting the digipot’s resistance based on various conditions and requirements. Some digipots come equipped with front panel switches or control logic as control units.

However, the vast majority will feature an increment or decrement asynchronous series bus instead. This asynchronous series bus relies on three signals to operate efficiently. The U/D signal indicates that the digipot’s wiper should move in order to increase or decrease resistance. The CS, or Chip Select, signal acts as an address input for several applications when enabled. Finally, the INC, or increment signal controls the wiper to adjust at the increment signal’s every falling edge.

Why digital potentiometers?

Why should engineers opt to embrace digital potentiometers over regular potentiometers? Digipots promise a host of additional benefits and enhanced functionality over their more traditional, mechanical counterparts. For example, while both offer a broad selection of end-to-end resistances and can be used interchangeably in most applications, digital potentiometers provide stronger protection against vibration and shocks. It is also known that mechanical potentiometers are more sensitive to oxidation and general wear and tear. Therefore, digital potentiometers are sure to last for longer periods of time, making them a cost-effective and obvious choice for most engineers from a long-term perspective.

Choosing digital potentiometers

There are a number of digipots available for sale, so how can you be sure that you’re investing in the right one for your project? Use a search engine, such as Octopart, specifically dedicated to helping you source the electronic components that you need. Simple, easy, and hassle-free.

Good luck!